#expanded polystyrene panels

Explore tagged Tumblr posts

Text

Explore our range of EPS panels at Vishay Porta Cabins Enterprises. Discover energy-efficient and versatile solutions for insulation, construction, and temperature control.

#eps panels#expanded polystyrene panels#energy-efficient panels#temperature control panels#customizable eps solutions#eps panel manufacturer#eps panel supplier

0 notes

Text

Expanded Polystyrene Insulated Panels Market is projected to reach $794.36 million by 2031 | AMR

0 notes

Text

Foam Insulation: The Modern Solution for Building Insulation

Introduction With rapid climate change and growing awareness of the importance of rationalizing energy consumption, building insulation has become a necessity, not a luxury. Among modern methods that have proven effective in thermal and water insulation, foam insulation stands out as one of the most prominent solutions relied upon by contracting companies and owners of both new and old buildings. What is this type of insulation? What distinguishes it from others?

What is Foam Insulation? Foam insulation is a type of insulation that uses a foam material sprayed or installed on surfaces, walls, ceilings, or floors to prevent heat or water leakage. Foam is characterized by its light weight, ease of installation, and high insulation effectiveness, making it an ideal choice in many cases.

Types of Foam Insulation

Spray Foam (Polyurethane) Sprayed onto surfaces using special devices.

After spraying, it expands to form a tight insulating layer.

It is used to insulate surfaces and walls.

Rigid Foam (Polystyrene Boards) Comes in the form of pre-fabricated panels that are installed on roofs or inside walls.

Used for insulating floors, ceilings, and walls.

Polyisocyanurate Foam Considered a highly efficient thermal insulation material.

Good fire and moisture resistance.

Benefits of Foam Insulation

Strong Thermal Insulation Reduces heat loss into the building in the summer or escape in the winter, reducing electricity bills and maintaining a stable temperature.

Excellent Waterproofing Prevents water from seeping into roofs or walls, reducing the chances of moisture and mold.

Lightweight Doesn't place an additional load on the building and can be used in older buildings.

Complete Sealing of Gap Unlike some traditional types of insulation, foam easily covers small gaps and cracks.

Insect and Mold Resistant Doesn't provide a suitable environment for fungal or insect growth.

Uses of Foam Insulation Insulating roofs (flat or sloping).

source

شركة كشف تسربات المياه بالخبر شركة كشف تسربات المياه بالدم��م كشف تسربات المياه الدمام بدون تكسير

Insulating underground and overhead tanks.

Insulating external and internal walls.

Insulating foundations to prevent water seepage from the ground.

Insulating basements to prevent moisture from rising.

Insulating cold rooms and factories.

How to Apply Foam Insulation Clean the surface thoroughly to remove dust and moisture.

Prepare the equipment for spraying or installation.

Spray the foam or install panels depending on the type used.

Cover the foam with a protective layer (such as an acrylic layer or UV-blocking paint).

Final testing to ensure the effectiveness of the insulation.

Comparison between Foam Insulation and Other Insulation Types Type: Thermal Efficiency, Water Resistance, Ease of Installation, Lifespan Foam: Excellent, Excellent, Easy, Long (20-30 years) Rock Wool: Good, Weak, Average, Average Fiberglass: Average, Weak, Easy, Short Polystyrene: Good, Good, Easy, Average

Disadvantages of Foam Insulation Despite its significant advantages, foam insulation has some disadvantages, including:

High initial cost compared to some other types of insulation.

It requires specialists for proper installation.

Some types are affected by ultraviolet rays if not properly covered with a protective layer.

Some types are flammable and non-fire-resistant.

Criteria for Choosing Foam Insulation When considering foam insulation, you should consider:

The type of roof (exposed, sloped, concrete, etc.).

The climatic conditions of the area.

The type of foam appropriate for the situation (thermal only or thermal and water).

The quality and experience of the implementing company.

The Environment and Foam Insulation Many manufacturers are now moving towards using environmentally friendly foam materials, free of chlorofluorocarbons (CFCs), which cause damage to the ozone layer. This makes foam a sustainable choice if produced and used responsibly.

Conclusion Foam insulation is one of the most effective and efficient insulation technologies available today, both thermally and water-wise. Despite its relatively high initial cost, its long-term results include significant energy savings and reduced building maintenance, making it a smart long-term investment. With the growing trend toward green and sustainable buildings, reliance on this type of insulation is expected to increase in the near future.

0 notes

Text

Tấm Xốp Cách Nhiệt EPS

EPS (Expanded Polystyrene) được sản xuất từ hạt nhựa Polystyrene giãn nở, với 98% thể tích là không khí.

Ưu điểm:

Trọng lượng rất nhẹ

Khả năng cách âm đạt 50dB

Không thấm nước, chống ẩm

Giá thành rẻ nhất trong các loại

Dễ cắt gọt, tạo hình

Ứng dụng:

Lót sàn, lót vách, lót mái tôn

Làm lõi cho panel EPS

Nâng sàn bê tông

tienphongplastic #tammutxopcachnhiet #tamxopeps #tamxopxps #tamxoppe

1 note

·

View note

Text

Can You Add a Roof to a Patio Enclosure?

Consider the benefits of a roof over your patio enclosure when enhancing your outdoor living spaces. Adding a roof can be a game-changer to create a cozy haven from the elements, increase your home’s value, or enjoy your outdoor space year-round. In this article, we’ll explore the various options, styles, and considerations for adding a roof to your patio enclosure, guiding you to make an informed choice.

Understanding Patio Enclosures

Patio enclosures are designed to extend your living space and seamlessly blend the indoors with the outdoors. They provide a versatile area where you can relax, entertain, or enjoy family gatherings while protected from the elements. With many designs available, you can tailor your patio enclosure to suit your style and home's architecture.

Why Add a Roof?

As you consider enhancing your patio enclosure, adding a roof offers several advantages:

Protection from Weather: A roof shields you from rain, snow, and harsh sunlight, allowing you to enjoy your patio throughout the year.

Increased Comfort: A roof allows your patio enclosure to remain cooler in the summer and warmer in the winter, providing a more comfortable, relaxing setting.

Enhanced Aesthetics: Roof designs can complement your home’s architecture and add visual appeal to your outdoor space.

Expanded Usability: A roof transforms your patio enclosure into a usable space for various activities, such as dining and playing games.

Types of Roofs for Patio Enclosures

When choosing a roof for your patio enclosure, several popular styles come into play. Each type offers distinct benefits and aesthetics to consider:

1. Gable Roofs

Gable roofs are characterized by their two sloping sides that meet at a peak. This design provides a traditional look and contributes to effective water shedding. Gable roof panels typically feature an engineered polystyrene core, which enhances insulation properties and overall structural integrity. This style allows for increased interior space, making it an excellent choice for gatherings and activities.

2. Flat or Single-Slope Roofs

Flat or single-slope roofs are simpler and often more modern. They work well for minimalist designs and are easier to install, making them a budget-friendly option. While they may not provide as much interior height as gable roofs, they still offer effective water drainage and can be integrated with existing structures.

3. Cathedral Roofs

Cathedral roofs feature high, vaulted ceilings for those seeking a more dramatic effect, creating an expansive feel within the enclosure. This style allows natural light to penetrate the space, enhancing the ambiance.

4. Studio Roofs

Studio roofs are a solid choice for a clean, contemporary look. Their simple, sloping design pairs well with modern aesthetics and can be easily integrated into various architectural styles.

Customization Options for Your Patio Roof

When it comes to patio enclosures, customization is key. You can tailor your roof to meet specific needs and preferences, ensuring it fits perfectly with your home. Here are some options to consider:

Insulation and Energy Efficiency

Opting for insulated panels constructed with polystyrene cores and aluminum skins provides excellent thermal performance. This can greatly enhance the comfort of your enclosed patio while lowering energy costs.

Skylights and Ventilation Features

Skylights can significantly increase natural light and make the space more open. Additionally, consider incorporating ventilation features like fan beam panels to maintain airflow throughout your enclosure.

Screen and Glass Options

Choosing between screen and glass panels depends on your desired protection from insects and weather. Screens provide excellent airflow while keeping bugs out, while glass panels offer unobstructed views and help control temperature.

Considerations Before Adding a Roof

Before proceeding with your patio enclosure roof project, keep the following factors in mind:

Local Building Codes and Regulations

Ensure you understand the local building codes and regulations that may impact your patio enclosure project. Complying with these guidelines will prevent complications later.

Budget and Costs

Consider your budget when selecting roofing materials and styles. While some options may be more affordable upfront, investing in quality materials can provide long-term benefits.

Professional Installation

Unless you have extensive construction experience, hiring professionals to install a closure roof is wise. The project must meet safety and quality standards.

Maintenance Requirements

Different roofing materials come with varying maintenance requirements. Be sure to consider the level of upkeep you’re willing to commit to enjoying your enclosure for years.

Conclusion

Adding a roof to your patio enclosure can significantly enhance your outdoor living experience. Various styles and customization options are available to create a space that meets your aesthetic preferences and functional needs.

Ready to explore the possibilities for your patio enclosure? Visit Screen Mobile of South Bend today to learn more about custom patio enclosures and outdoor/indoor screen solutions. Let’s turn your outdoor dreams into reality!

1 note

·

View note

Text

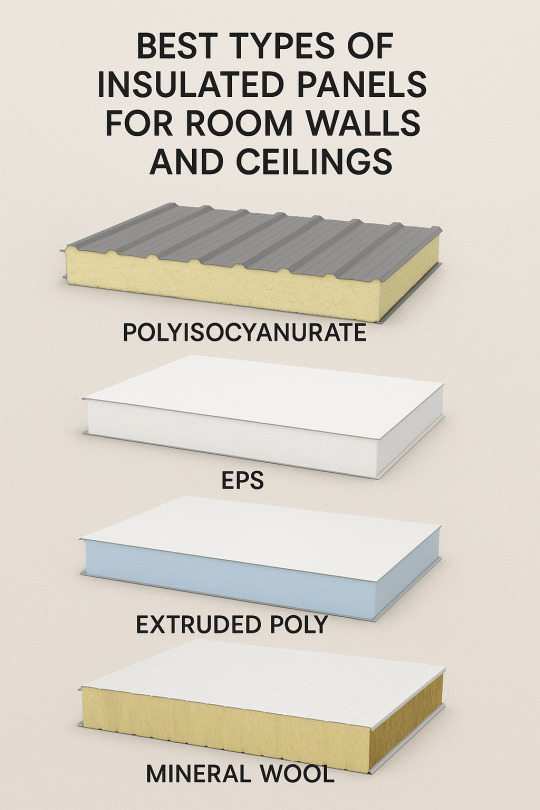

Best Types of Insulated Panels for Room Walls and Ceilings

In modern construction, energy efficiency, durability, and speed are more important than ever. Whether you're building a residential home, commercial office, warehouse, or prefab structure, choosing the right insulation for walls and ceilings is key to maintaining indoor comfort and reducing energy costs.

Insulated panels are prefabricated systems that combine insulation and structural support in a single solution. They’re ideal for temperature control, noise reduction, and structural strength. Here's a look at the best types of insulated panels for room walls and ceilings, each with its own advantages:

1. Polyisocyanurate (PIR) Panels

Polyisocyanurate, or PIR, is one of the highest-performing thermal insulation materials used in construction today. These panels consist of rigid foam sandwiched between two metal or board layers.

Key Benefits:

Superior thermal efficiency – high R-value per inch

Fire resistance – self-extinguishing properties

Lightweight and durable – easy to handle and install

Moisture resistance – ideal for both indoor and outdoor use

PIR panels are ideal for temperature-controlled spaces such as cold storage, server rooms, and industrial buildings.

2. Expanded Polystyrene (EPS) Panels

EPS panels are made from expanded polystyrene foam, known for its excellent insulating properties and cost-effectiveness. These panels are widely used in prefabricated and modular buildings.

Key Benefits:

Affordable insulation solution

Good thermal and acoustic performance

Lightweight and easy to cut or install

Environmentally friendly and recyclable

EPS panels are great for residential rooms, partitions, and standard prefab structures where cost and speed are priorities.

3. Extruded Polystyrene (XPS) Panels

Extruded polystyrene is a denser and stronger form of polystyrene insulation. XPS panels offer excellent thermal performance and resistance to moisture, making them ideal for high-humidity environments.

Key Benefits:

High compressive strength

Excellent moisture and water resistance

Smooth surface finish

Long-term durability

These panels are often used for roofs, ceilings, basements, and cold storage facilities.

4. Mineral Wool Panels

Mineral wool (or rock wool) panels are made from natural stone or slag fibers. Known for their fire resistance and soundproofing qualities, these panels are ideal for buildings where fire safety is a top priority.

Key Benefits:

Non-combustible and fire-resistant

Excellent sound insulation

Resistant to pests, mold, and rot

Eco-friendly and recyclable

They are commonly used in commercial and industrial spaces, especially in applications requiring acoustic control and fire safety.

Conclusion

The choice of insulated panels depends on your building's requirements—whether it’s superior thermal performance, moisture resistance, acoustic insulation, or fire safety.

Polyisocyanurate is best for energy efficiency, EPS offers an economical and lightweight option, XPS excels in moisture-prone areas, and Mineral Wool provides unbeatable fire and sound insulation.

Investing in the right insulation solution helps you reduce energy bills, enhance occupant comfort, and extend the life of your building.

Looking for high-quality insulated panel solutions? Partner with trusted manufacturers like Engko for expert guidance and top-grade materials tailored to your project.

#prefab#pre engineered building manufacturers#prefabricated#peb#prefabricated structure#warehouse#industrial

1 note

·

View note

Text

Cold Chain Packaging Market Poised for Transformation with Emerging Technologies and Eco-Friendly Materials

The cold chain packaging market is experiencing robust growth as industries demand more efficient and reliable temperature-sensitive logistics solutions. Cold chain packaging refers to systems and materials used to maintain a consistent low-temperature range for perishable products during storage and transportation. It plays a pivotal role in preserving the integrity of products such as pharmaceuticals, food and beverages, chemicals, and biological samples.

Rising Demand in Key Industries

The primary driver behind the growth of the cold chain packaging market is the increasing global demand for temperature-controlled pharmaceuticals and biologics. With the rise in chronic diseases and the expansion of biopharmaceuticals, there is a pressing need for secure and reliable cold chain systems to maintain product efficacy and safety. The COVID-19 pandemic further amplified this need, showcasing the importance of efficient cold chain logistics in vaccine distribution.

In the food and beverage industry, globalization of trade and shifting consumer preferences toward fresh and organic products have necessitated high-performance cold chain packaging. Perishable foods like dairy, meat, seafood, and frozen goods require stable temperature environments to prevent spoilage, maintain quality, and comply with stringent food safety regulations.

Innovation in Packaging Materials and Technology

Technological advancements are playing a crucial role in the evolution of cold chain packaging. The development of phase change materials (PCMs), vacuum insulated panels (VIPs), and smart packaging with temperature indicators and GPS tracking have revolutionized the way sensitive goods are stored and transported. These technologies help companies monitor temperature in real-time and mitigate risks during transit, ensuring product safety and reducing losses.

Sustainable and reusable cold chain packaging solutions are also gaining traction. With increasing environmental concerns and regulations on plastic use, companies are adopting eco-friendly packaging materials made from recycled content or biodegradable polymers. Reusable insulated containers, along with active and passive refrigeration systems, are becoming standard in many cold chain operations to minimize waste and optimize cost-efficiency.

Market Segmentation and Regional Insights

The cold chain packaging market can be segmented by product type, material, application, and geography. Popular product types include insulated containers and boxes, refrigerants (such as gel packs and dry ice), labels, and temperature monitoring devices. Materials used range from polystyrene foam and polyurethane to corrugated fiberboard and advanced insulation films.

Geographically, North America holds a significant share of the market due to its established pharmaceutical and processed food industries, along with a strong regulatory framework. Europe follows closely, driven by stringent quality and safety standards. However, the Asia-Pacific region is projected to grow at the highest CAGR, owing to rising healthcare investments, increasing food exports, and expanding cold storage infrastructure in countries like China and India.

Challenges and Opportunities

Despite the promising outlook, the cold chain packaging market faces several challenges. High initial investment and maintenance costs for temperature-controlled packaging systems can deter small and medium-sized enterprises. Inconsistent infrastructure in developing economies, along with varying regulations across regions, also hinders market expansion.

However, these challenges present opportunities for innovation and collaboration. Companies are investing in R&D to develop low-cost, high-efficiency packaging alternatives. Partnerships between packaging manufacturers, logistics providers, and technology firms are creating integrated cold chain ecosystems. Furthermore, digitalization and automation are enhancing traceability and compliance, thereby improving overall supply chain efficiency.

Future Outlook

The future of the cold chain packaging market looks promising, with projections indicating consistent growth through 2030. Increasing globalization, urbanization, and online grocery and pharmaceutical deliveries are expected to further drive demand. As companies strive to meet regulatory compliance, reduce waste, and improve sustainability, innovation in materials and smart packaging technologies will remain at the forefront.

Emerging trends such as blockchain for enhanced traceability, AI for demand forecasting, and the use of IoT sensors for real-time monitoring will likely shape the next generation of cold chain packaging. Governments and private sector players must work collaboratively to strengthen infrastructure and standardize practices globally.

In summary, the cold chain packaging market is evolving rapidly in response to changing industry needs, consumer expectations, and environmental concerns. By embracing technological advancements and sustainable practices, the industry is set to meet the growing demand for safe and efficient cold chain logistics worldwide.

#ColdChain#ColdChainPackaging#ColdChainLogistics#TemperatureControlled#PharmaLogistics#FoodLogistics

0 notes

Text

Foam Insulation Market Overview and Growth Outlook

The foam insulation market is experiencing steady growth as industries and households seek better energy efficiency, improved indoor comfort, and lower environmental impact. Foam insulation materials are widely used in construction, refrigeration, automotive, and packaging sectors due to their high thermal resistance and lightweight properties.

Market Overview

Foam insulation involves the use of materials like polyurethane, polystyrene, and phenolic foam to reduce heat transfer. These materials are applied in walls, roofs, pipes, and floors to create a thermal barrier. They help keep buildings warm in winter and cool in summer, reducing the need for heating and cooling systems.

Key types of foam insulation include:

Spray Foam: Applied on-site, it expands and fills gaps, offering excellent air sealing.

Rigid Foam Boards: Pre-formed panels used in walls, roofs, and foundations.

Foam-in-Place: Installed during construction to fit into tight spaces.

Growth Drivers

Energy Efficiency Regulations Governments around the world are promoting energy-saving buildings. Foam insulation helps meet building codes and energy standards, encouraging its use in new and existing structures.

Rising Construction Activity Growing residential and commercial construction, especially in developing countries, is driving demand for insulation materials.

Increased Awareness of Environmental Impact As people and businesses aim to lower carbon emissions, foam insulation plays a key role in making buildings more eco-friendly by reducing energy usage.

Technological Advancements Innovations in foam materials have led to better performance, longer durability, and improved fire resistance. Some products are also made with eco-friendly or recycled materials.

Growth in Refrigeration and Cold Storage Foam insulation is widely used in cold storage facilities and refrigerators to maintain low temperatures efficiently. This sector is growing due to demand from food, pharma, and logistics industries.

Challenges

Environmental Concerns: Some foam types contain chemicals that may harm the environment, pushing manufacturers to develop greener alternatives.

High Initial Costs: Foam insulation can be more expensive upfront compared to traditional materials, though it saves money in the long run through energy savings.

Flammability and Safety Regulations: Ensuring that insulation materials meet fire safety standards is essential, especially in commercial buildings.

Future Outlook

The foam insulation market is expected to grow steadily over the next decade. Key trends shaping the future include:

Green Building Movement: More construction projects will prioritize sustainable materials, boosting demand for eco-friendly foam products.

Smart Cities and Infrastructure Development: Urban expansion and modernization efforts will increase the need for advanced insulation solutions.

Product Innovation: Development of low-emission, high-performance foams will help meet both environmental and energy goals.

Regions like North America, Europe, and Asia-Pacific are expected to lead the market due to rising construction, government incentives, and climate-conscious consumers.

Conclusion

The foam insulation market is growing as the world looks for better ways to save energy and protect the environment. With continued innovation, supportive regulations, and rising demand across industries, foam insulation will remain a key material for modern, sustainable living and construction.

0 notes

Text

Foam Insulation: The Modern Technology for Thermal and Sound Insulation

شركة كشف تسربات المياه بجدة

شركة تجديد حمامات بالرياض

شركة ترميم حمامات بالرياض

Foam Insulation: The Modern Technology for Thermal and Sound Insulation Thermal and sound insulation are among the most important elements of modern construction, directly contributing to improving the quality of life inside buildings, whether residential, commercial, or industrial. With the advancement of insulation technologies, foam insulation has emerged as one of the best and most efficient types of insulation currently used, due to its flexibility, high efficiency, and ease of application.

What is Foam Insulation? Foam insulation is a type of insulation that uses a lightweight foam material known as "foam." This chemical substance is produced by mixing two basic components: polyol and isocyanate. When mixed, the foam expands to fill the gaps and cover the entire surface, forming a strong insulating layer.

Foam can be applied in two ways:

Spray Foam: Sprayed directly onto surfaces using special equipment.

Foam Boards: Installed manually on surfaces.

Types of Foam Insulation Polyurethane Foam: The most widely used, it offers high thermal and sound insulation, and is also resistant to water and moisture.

Polyethylene Foam: It is often used for sound insulation and has good shock absorption.

Polystyrene Foam: Available in the form of panels, it is used for thermal insulation of roofs, walls, and floors.

Closed-cell spray foam: Denser and more durable, suitable for exterior surfaces, and highly water-resistant.

Open-cell spray foam: Lighter and less dense, yet more flexible, it is often used for sound insulation.

Advantages of Foam Insulation ✅ Effective Thermal Insulation: Prevents heat from the outside to the inside and vice versa, reducing the need for air conditioning or heating.

✅ Excellent Sound Insulation: Reduces noise transmission between rooms or from the outside to the inside.

✅ Moisture and Water Resistance: It does not absorb water, protecting surfaces from water leaks and mold.

✅ Accurate Coverage: Due to its foamy nature, foam fills all gaps and cracks, preventing air leakage.

✅ Reduces Energy Consumption: It helps lower electricity bills by improving energy efficiency.

✅ Lightweight: It does not place an additional burden on surfaces or structures.

✅ Long Lifespan: It does not corrode easily and can last for years without maintenance.

Disadvantages of Foam Insulation ❌ Relatively High Cost: It is more expensive than some traditional types of insulation, especially closed-cell spray foam.

❌ Requires Professional Technicians: Foam application must be performed by specialists to ensure good coverage and avoid future problems.

❌ Chemicals: Some types of foam may contain volatile organic compounds (VOCs), which can be harmful if not used properly.

Uses of Foam Insulation Roof Insulation: It is one of the best types of insulation for roofs, as it prevents heat and water leakage.

Wall Insulation: It is used inside walls to strengthen thermal and sound insulation.

Floor Insulation: It reduces the transfer of cold from the ground, providing greater comfort, especially in winter.

Industrial Buildings and Warehouses: It helps maintain suitable temperatures inside industrial facilities.

Cars and Refrigerators: Foam is used in the manufacture of cars and refrigerators as an insulating material.

How to Install Foam Insulation (Spraying): Clean the surface thoroughly of dust and oils.

Cover areas not to be insulated, such as windows and air conditioners.

Spray the foam using special equipment, and it begins to expand within seconds.

Level and trim excess material to obtain a flat surface.

Cover the foam with a protective layer (such as a waterproofing layer or protective paint) to maintain its efficiency.

The Difference Between Foam Insulation and Other Insulation

Comparison: Rockwool Foam Insulation vs. Cement Insulation Efficiency: Very High, Medium, Weak Weight: Light, Relatively Heavy, Heavy Water Resistance: High (Excellent), Weak, Medium Ease of Application: Easy and Quick, Requires Time and Effort, Difficult Lifespan: Long, Medium Foam Insulation and Sustainability With the global trend toward sustainability and environmental conservation, environmentally friendly foam types have emerged that do not release harmful compounds during manufacturing or after installation. The reduced energy consumption resulting from foam use also reduces carbon emissions, making it a positive contributor to environmental protection.

Tips Before Choosing Foam Insulation Make sure you choose the right type of foam for the nature of the building or roof.

Choose a company with experience in installation to ensure results.

Request a warranty on the material and workmanship.

Ask about the type of chemicals used and their compliance with safety standards.

Don't neglect the final protection of the foam, whether with an insulating paint layer or a waterproofing layer.

Conclusion Foam insulation is a smart and cost-effective long-term option, especially in light of rising energy costs and the growing need for environmental comfort within homes and institutions. Despite its initial cost, its significant energy-saving and weather-protection benefits make it a successful investment for anyone seeking to build or develop a modern, sophisticated building.

0 notes

Text

Why Modular Cold Room Manufacturers Are Revolutionizing the Cold Storage Industry

In today’s fast-paced world, where businesses across industries are relying more on efficient and scalable storage solutions, modular cold room manufacturers have become key players in transforming the cold storage landscape. Whether it's for pharmaceuticals, food storage, or other sensitive products, modular cold rooms offer unparalleled benefits in both flexibility and efficiency.

But why are modular cold rooms gaining so much attention? What makes them the preferred choice for businesses worldwide? Let’s dive deeper into how cold room manufacturers are helping reshape the cold storage industry and why your business should consider modular solutions.

What Are Modular Cold Rooms?

Modular cold rooms are pre-engineered and easily customizable temperature-controlled storage units. Unlike traditional cold storage rooms, which often require lengthy installation and significant on-site construction, modular cold rooms are designed to be assembled quickly and adapted to meet specific business needs.

These cold rooms are made from insulated panels, typically using high-quality materials such as cold room panels, which help maintain the desired temperature range efficiently. The modular design allows for easy expansion or reconfiguration, making them ideal for businesses that need flexible and scalable storage solutions.

Why Modular Cold Rooms Are Gaining Popularity

Cost-Effectiveness and Speed One of the key reasons cold room manufacturers are increasingly turning to modular solutions is the cost savings they offer. Modular cold rooms are quicker to assemble and install compared to traditional cold storage setups, leading to significant reductions in labor costs and overall construction time. Plus, their scalable nature means businesses can start with smaller units and expand as their storage needs grow.

Flexibility and Customization Modular cold room manufacturers offer a high degree of customization, enabling businesses to design a cold storage solution that fits their exact specifications. From temperature requirements to the size and layout of the storage space, modular systems can be easily tailored to meet the needs of various industries, including food production, pharmaceuticals, and even agriculture.

Energy Efficiency and Sustainability As environmental sustainability becomes more important, cold storage plant manufacturers are focusing on energy-efficient technologies. Modular cold rooms, thanks to their advanced insulation materials and design, offer better temperature retention, leading to lower energy consumption. This not only helps businesses reduce operational costs but also contributes to sustainability goals by minimizing the carbon footprint of their operations.

Durability and Long-Term Investment Cold storage manufacturers know that longevity is key when it comes to cold storage solutions. Modular cold rooms are built to last, often withstanding extreme weather conditions and high demand. Their robust structure and high-quality components ensure that they provide dependable service for many years, which is a great return on investment for businesses that depend on efficient storage.

Compliance and Safety Standards Many industries, particularly food and pharmaceuticals, require strict adherence to temperature and safety standards. Modular cold rooms are designed to comply with various industry regulations, ensuring that businesses can safely store perishable goods and meet regulatory requirements. This is a significant advantage for businesses that need reliable and compliant storage solutions.

The Role of Cold Room Panel Manufacturers in Efficiency

One of the unsung heroes of the modular cold room is the cold room panel. These insulated panels are the backbone of any cold storage system, ensuring temperature stability and preventing energy loss. The high-quality materials used in these panels, such as polyurethane and polystyrene, ensure that the cold room maintains the required temperature while being energy-efficient.

Cold room panel manufacturers play a crucial role in delivering durable, energy-efficient, and customizable solutions that support the entire cold storage system. With advancements in insulation technologies, these panels are becoming lighter, stronger, and more efficient—making modular cold rooms even more cost-effective and reliable.

The Future of Cold Storage: What to Expect

As demand for cold storage grows across sectors like e-commerce, pharmaceuticals, and food safety, businesses are looking for innovative solutions that provide flexibility, cost-efficiency, and scalability. Modular cold rooms fit these criteria perfectly, offering adaptable and efficient storage solutions that can grow alongside a business.

Cold storage manufacturing companies are expected to continue innovating with modular designs, incorporating better insulation materials, smarter temperature control systems, and even IoT-enabled features for remote monitoring and control. These advancements will further enhance the value of modular cold rooms and make them an essential part of the modern cold storage industry.

Conclusion: Invest in Modular Cold Storage Solutions

Modular cold rooms are not just a trend—they are a fundamental shift in how businesses approach cold storage. With their cost savings, energy efficiency, flexibility, and long-term durability, they offer a solution that meets the demands of today’s fast-paced industries.

If you're looking to invest in a reliable, scalable, and sustainable cold storage solution, EPACK Prefab is here to help. As one of the leading cold room manufacturers in India, we specialize in creating custom cold storage solutions tailored to your business needs. Whether you're looking for modular cold rooms or full-scale cold storage plants, we have the expertise and technology to deliver top-tier, durable, and energy-efficient systems.

Contact EPACK Prefab today to learn more about our modular cold room solutions and how we can help your business stay ahead of the competition.

Related Post - Finding the right Commercial Prefabricated Cold Storage Facility

#ColdRoomManufacturers#ModularColdRoomManufacturers#ColdStorageManufacturers#ColdStorageManufacturingCompanies#ColdRoomPanelManufacturers#ColdStoragePlantManufacturers#ColdStorageSolutions#ModularColdRooms#PEBColdStorage#EnergyEfficientColdRooms#ColdRoomInstallation#ColdRoomTechnology#SustainableColdStorage#IndustrialColdStorage#EPACKPrefab#ColdStorageInnovation

1 note

·

View note

Text

Hunter Concrete Pumping: Supplying Strong, Energy-Efficient Fox Blocks

As demand grows for sustainable and energy-efficient construction materials in Central Texas, Hunter Concrete Pumping proudly announces its continued commitment to supplying high-quality Fox Blocks ICF Austin builders can trust. Known for its exceptional insulation properties and durability, Fox Blocks (Insulated Concrete Forms) offer a modern solution for eco-conscious residential and commercial projects alike. Based in Central Texas, Hunter Concrete Pumping has built a strong reputation as one of the most trusted concrete companies in Austin Texas. With decades of experience in concrete delivery and placement, the company continues to evolve to meet the needs of modern builders — especially those seeking environmentally friendly alternatives. As a Fox Blocks supplier Austin TX contractors can rely on, Hunter ensures timely delivery and expert knowledge of how to integrate ICF systems into both large-scale and small-scale construction jobs. Why Fox Blocks? Fox Blocks provide a sustainable and highly efficient building envelope. Each block is made of two panels of expanded polystyrene (EPS) connected by polypropylene webs. When stacked and filled with concrete, they create a solid, reinforced wall that delivers superior insulation, soundproofing, and fire resistance. For builders in the Austin region, where energy efficiency is a top concern, this type of product can significantly reduce heating and cooling costs while promoting environmental responsibility. Supporting Austin’s Growing Construction Needs As Austin continues to grow, so does the need for sustainable infrastructure. The demand for homes and commercial buildings that are energy-efficient and storm-resistant has increased substantially. Hunter Concrete Pumping is stepping in to meet these needs by providing not just high-performance concrete solutions, but also modern alternatives like Fox Blocks. Hunter Concrete Pumping is more than just a delivery service. The company provides in-depth consultations, seamless logistics, and knowledgeable support for integrating ICF into projects of all sizes. From custom homes in Pflugerville to commercial developments in downtown Austin, Hunter's expertise helps projects run smoothly and finish on time. Your Partner in Advanced Concrete Solutions With a full fleet of concrete pumps and a seasoned crew, Hunter Concrete Pumping offers more than just materials — they offer peace of mind. Their reputation among concrete companies in Austin Texas is built on reliability, professionalism, and a genuine passion for helping clients achieve lasting results. From planning to pouring, Hunter is your go-to partner for superior concrete and cutting-edge solutions like Fox Blocks. As Austin continues to expand and evolve, Hunter is ready to help build a stronger, more energy-efficient future — one block at a time. Original Source: https://bit.ly/4jhtQwq

0 notes

Text

What is the best type of insulation for an asphalt roof?

Did you know that an uninsulated roof can account for up to 26% of heat loss in your home? This not only leads to higher energy bills but also affects indoor comfort. If you're considering asphalt roofing repairs or installations, selecting the right insulation is crucial for enhancing energy efficiency and maintaining a comfortable living environment.

Choosing the appropriate insulation for your asphalt roof can be a daunting task, especially with the variety of materials available. Each type offers unique benefits, and making an informed decision is essential for the long-term durability, safety, and curb appeal of your property.

In this article, we'll explore the best types of insulation suitable for asphalt roofs, providing you with friendly, straightforward advice to help you make the best choice for your home.

Understanding Roof Insulation and Its Importance

Roof insulation acts as a barrier to heat flow, keeping your home warmer in the winter and cooler in the summer. Proper insulation reduces energy consumption, leading to lower utility bills and a reduced carbon footprint. For asphalt roofs, selecting the right insulation material ensures compatibility and optimal performance.

Types of Insulation Suitable for Asphalt Roofs

Fiberglass Insulation

Description: Composed of fine glass fibers, fiberglass insulation is available in batts, rolls, or loose-fill forms.

Benefits:

Cost-Effective: Fiberglass is one of the most affordable insulation materials, making it a popular choice for homeowners.

Thermal Performance: It offers good thermal resistance, helping to maintain indoor temperatures.

Fire Resistance: Fiberglass is non-combustible, adding a layer of fire safety to your home.

Considerations:

Installation: Proper installation is crucial to prevent gaps that can reduce effectiveness.

Moisture Sensitivity: Fiberglass can lose its insulating properties when wet, so ensuring a moisture barrier is important.

Mineral Wool (Rock Wool) Insulation

Description: Made from volcanic rock, mineral wool is dense and durable.

Benefits:

Excellent Thermal Resistance: Provides high R-values, enhancing energy efficiency.

Sound Insulation: Its density helps in reducing external noise.

Fire Resistance: Mineral wool can withstand high temperatures, offering added fire protection.

Considerations:

Cost: Generally more expensive than fiberglass.

Weight: Heavier than other insulation types, which may require additional structural support.

Spray Foam Insulation

Description: A liquid that expands into a foam, sealing gaps and providing insulation.

Benefits:

Air Sealing: Effectively fills cavities, preventing air leaks.

High R-Value: Offers superior thermal resistance per inch compared to other materials.

Moisture Barrier: Closed-cell spray foam acts as a barrier against moisture.

Considerations:

Cost: One of the more expensive insulation options.

Professional Installation: Requires skilled professionals for proper application.

Rigid Foam Board Insulation

Description: Panels made from polystyrene, polyisocyanurate, or polyurethane.

Benefits:

High Insulating Value: Provides excellent thermal resistance.

Moisture Resistance: Particularly effective in preventing moisture intrusion.

Structural Support: Adds rigidity to the roofing system.

Considerations:

Installation: Must be cut to fit, and seams should be sealed to prevent thermal bridging.

UV Sensitivity: Some foam boards can degrade under UV exposure if not properly covered.

Factors to Consider When Choosing Insulation

Climate: In warmer climates, insulation that also reflects heat is beneficial, while in colder regions, higher R-value materials are preferable.

Roof Design: The pitch and structure of your roof can influence the type of insulation that is most suitable.

Budget: Balancing cost with performance is key; investing in higher-quality insulation can lead to long-term savings.

Environmental Impact: Some materials have a lower environmental footprint, which may be important for eco-conscious homeowners.

Installation Considerations

Proper installation is vital to ensure the effectiveness of your chosen insulation. Here are some steps to consider:

Hire a Professional: Engaging a qualified contractor ensures that insulation is installed correctly, maximizing its benefits.

Ensure Ventilation: Adequate ventilation prevents moisture buildup, which can compromise insulation performance.

Check for Compatibility: Ensure that the insulation material is compatible with asphalt shingles to avoid any potential issues.

Conclusion

Selecting the best insulation for your asphalt roof is a significant decision that impacts your home's energy efficiency, comfort, and safety. It can be done by considering the types of insulation available and evaluating factors such as climate, budget, and roof design. You can make an informed choice that suits your specific needs. Remember, proper installation is just as important as selecting the right material, so consider consulting with a professional to achieve the best results.

1 note

·

View note

Text

The Advantages of ZENITH 940SC Fully Automatic Mobile Multilayer Machine in Block Making

The infographic highlights the key advantages of the ZENITH 940SC Fully Automatic Mobile Multilayer Machine in block making. It covers:

✅ Widest Production Scope: Supports standard, nonstandard, and niche concrete blocks & pavers for diverse market needs. ✅ Advanced Control System: Intuitive Touch Panel with Siemens SPS for seamless operation and quick mold adjustments. ✅ Superior Precision & Durability: Robust columns, bearings, and synchronized movements ensure stability and accuracy. ✅ High-Performance Hydraulics & Customization: Hydraulic cylinders enable smooth operation, with optional upgrades enhancing performance. Additional features like a rotating tamper head and polystyrene core insertion expand production capabilities.

For more details, visit www.apollozenith.com

#ZENITH940SC#BlockMakingMachine#ConcreteBlocks#PaverProduction#MultilayerMachine#ConstructionTechnology

0 notes

Text

Lightweight Construction Materials: Advantages and Applications

Introduction

The construction industry is evolving at a fast pace, with a focus on new materials that ensure efficiency, sustainability, and longevity. One of the most significant advancements in recent years is the use of lightweight construction materials. best home builders in gurgaon These materials provide numerous advantages in terms of cost savings, ease of application, and environmental sustainability.

For developers and builders of Gurgaon, it is necessary to learn about the benefits of lightweight construction materials. Being a building contractor of Gurgaon, one of the leading house builders of Gurgaon, or part of leading integrating such materials in your project can enhance construction quality without raising overall project costs high.

What Are Lightweight Building Materials?

Lightweight building materials are building components designed to be much lighter than conventional materials but very strong and durable. home builders in gurgaon The most popular ones are:

Aerated Autoclaved Concrete (AAC) Blocks

Lightweight Concrete

Structural Insulated Panels (SIPs)

Foam Concrete

Fiberglass and Carbon Fiber Reinforced Polymers

Lightweight Steel and Aluminum Alloys

Expanded Polystyrene (EPS) Panels

Lightweight building materials are excellent insulators, home contractors in gurgaon fire and seismic activity-resistant, and thus especially ideal for residential and commercial construction projects.

Advantages of Lightweight Construction Materials

1. Reduced Structural Load

Reduced structural load is certainly the biggest benefit of light materials. Buildings made of such materials are less strenuous to support, and hence they are ideal for high-rise buildings and other complex designs. Construction companies in Gurgaon prefer such materials to ensure long-lasting structural stability without boosting the cost of construction.

2. Cost Savings

Lightweight materials are very cost-effective. custom home builders in gurgaon They use less material for transportation, less labor for installation, and less support structure, making the project cost-effective overall. Builders in Gurgaon employ these materials to deliver affordable housing without compromising on quality.

3. Increased Energy Efficiency

Materials like AAC blocks and SIPs also provide better thermal insulation, which reduces the consumption of artificial cooling and heating. This is energy-saving, and people as well as companies can reduce expenses. Luxury house builders in Gurgaon use such materials to build green homes with optimum comfort.

4. Reduced Construction Time

Light materials are easier to handle and install, significantly reducing construction time. Prefabricated panels and modular construction techniques also accelerate project delivery, hence appropriate for quick urban development.

5. Sustainability and Eco-Friendliness

With the industry trend shifting in favor of sustainability, lightweight material usage plays a key role in reducing carbon footprint. The majority of these materials include recycled units or lower-energy-input processes for their production. Construction companies in Gurgaon that are engaged in customized homes with green solutions incorporate lightweight materials to keep up with green building.

6. Enhanced Seismic Resistance

In seismically active areas, light building materials reduce the risk of structural failure. Since they exert less force during seismic movement, they maximize a building's earthquake resistance, new home builders in gurgaon and therefore they are the most sought-after building contractors in Gurgaon.

7. Flexible Design Applications

Whatever could be the task of constructing a modern commercial building, luxury villa, or affordable residence, lightweight building materials are offering design freedom. They allow freedom to express innovative building designs without sacrificing strength and resistance in order to impart the buildings structural longevity.

Applications of Lightweight Building Materials

1. Residential Houses

Lightweight building materials are valuable to Gurgaon's leading house builders. AAC blocks, insulated panels, and foam concrete are used to build energy-efficient homes offering durability and comfort.

2. Commercial and Office Spaces

Lightweight materials are commonly used in the building of Gurgaon's leading office spaces. Skyscraper office buildings benefit from the fact that these materials illuminate the load on the building while offering industry-leading insulation and soundproofing.

3. Industrial and Warehousing Buildings

Most of the construction firms in Gurgaon use lightweight materials for building factories and warehouses. residential contractors in gurgaon They are easy to install and are affordable, making them the most suitable for large-scale industrial building.

4. Retrofits and Remodels

Lightweight materials are most suitable for remodeling existing older structures. custom builders in gurgaon They improve energy efficiency, strength, and overall aesthetics without adding additional loads to the foundation.

5. Villas and Luxury Farmhouses

Lightweight construction materials are part of the package when designing the best farmhouses in Gurgaon. Efficient in energy use and environmentally friendly with insulation, these materials aid in the construction of luxurious, cozy, and green farmhouses.

Choosing the appropriate lightweight construction material for your project

Choosing the proper light building material is dependent upon the project's nature, cost, and climate. Some of the considerations are:

For projects that are constructed locally: AAC blocks, SIPs, and foam concrete make effective long-duration insulators.

For commercial buildings: Steel, aluminum composite, and modular panels make effective load-carrying capacities with aesthetic appeal.

For industrial applications: EPS panels, fiber-reinforced plastics, and lightweight concrete make for strength and economy.

For green development projects: Green composites and recycled lightweight material aid green building projects.

Conclusion

The use of light construction materials is revolutionizing the construction sector. Be you a Gurgaon house builder, a Gurgaon residential constructor, or a part of construction companies in Gurgaon, their usage can be a boon of immense benefit regarding efficiency, cost-effectiveness, and eco-friendliness.

KP Organisation is the forerunner of new building techniques, employing the best in lightweight material technology to provide strong, energy-efficient, and economical buildings. With innovation in material technology, we assure you that our work is of superior quality and strength.

Looking for expert guidance on light construction? Contact us now and discover how we can help you build smarter, stronger, and greener structures!

0 notes

Text

Packaging Protection: Ensuring Safety and Sustainability in Modern Logistics

Introduction

Packaging protection plays a crucial role in safeguarding goods during transit, storage, and handling. Whether it’s fragile consumer products, industrial components, or perishable items, proper packaging ensures that products reach their destination in optimal condition. With the rise of e-commerce, globalization, and evolving supply chain dynamics, the demand for innovative and sustainable packaging protection has grown significantly.

This article delves into the importance of packaging protection, key materials and techniques used, challenges faced by industries, and how modern solutions are shaping the future of secure packaging.

The Importance of Packaging Protection

Prevention of Product Damage Packaging protection is essential for preventing damage caused by impact, vibrations, compression, or environmental factors. Whether a product is fragile like glassware or electronics, or robust like industrial machinery, the right packaging ensures minimal risk during handling and transportation.

Cost Reduction Businesses invest in protective packaging to reduce financial losses caused by product damage or returns. Effective packaging can lower operational costs by preventing material waste and reducing additional transportation expenses due to damaged goods.

Consumer Satisfaction Well-packaged products enhance customer experience. Damaged or poorly protected products lead to negative reviews, returns, and loss of brand reputation. Protective packaging ensures customers receive items in perfect condition, improving brand trust.

Regulatory Compliance Many industries, such as pharmaceuticals, food, and hazardous goods, must adhere to strict packaging regulations. Proper protective packaging ensures compliance with safety and quality standards.

Key Materials Used in Packaging Protection

The choice of materials for packaging protection depends on the type of product, handling conditions, and industry requirements. Some commonly used materials include:

Corrugated Cardboard

Lightweight, cost-effective, and recyclable.

Provides cushioning and structural support.

Used in boxes, dividers, and partitions.

Foam Inserts

Ideal for cushioning fragile items.

Available in polyethylene, polyurethane, and expanded polystyrene (EPS).

Commonly used for electronics, glassware, and medical devices.

Bubble Wrap & Air Pillows

Offer excellent shock absorption.

Reusable and available in biodegradable options.

Often used for wrapping delicate items and filling empty spaces in packages.

Plastic and Honeycomb Sheets

Provide structural strength and reusability.

Commonly used in industrial and automotive packaging.

Moisture-resistant and impact-absorbent.

Molded Pulp & Paper-Based Protective Packaging

Eco-friendly alternative to plastic.

Made from recycled paper pulp.

Used for food, electronics, and consumer goods packaging.

Types of Protective Packaging Solutions

Protective packaging comes in various forms, each designed to cater to different industries and transportation conditions:

Void Fillers & Cushioning Solutions

Used to fill empty spaces within packaging to prevent movement.

Includes air pillows, foam inserts, crinkle paper, and biodegradable peanuts.

Edge and Corner Protectors

Protects the most vulnerable parts of a product or package.

Commonly used for furniture, glass panels, and electronic devices.

Pallet Wrapping & Strapping

Ensures stability of stacked goods during transportation.

Includes shrink wrap, stretch film, and plastic straps.

Shock Absorption & Impact Resistance

Uses foam-based materials, corrugated structures, and honeycomb panels.

Protects products from shocks, drops, and rough handling.

Weatherproof & Moisture-Resistant Packaging

Essential for long-distance and outdoor storage.

Includes plastic films, aluminum foils, and coated paper.

Challenges in Packaging Protection

Despite advancements in packaging technology, several challenges persist:

Balancing Cost and Efficiency

High-quality protective packaging often increases costs.

Businesses must find cost-effective yet durable packaging solutions.

Sustainability Concerns

Traditional packaging materials like plastics contribute to environmental waste.

Transitioning to sustainable materials is crucial for eco-conscious industries.

Evolving Supply Chain Complexities

Global shipping demands robust packaging solutions that can withstand extreme conditions.

Packaging must adapt to changes in transportation and storage methods.

Future Trends in Packaging Protection

Biodegradable & Sustainable Packaging

Eco-friendly alternatives, such as mushroom-based packaging, biodegradable plastics, and molded pulp, are gaining popularity.

Smart Packaging Technologies

The use of RFID tags, temperature indicators, and QR codes enhances supply chain visibility.

Helps track product conditions and reduce losses.

Reusable & Returnable Packaging

Many industries are adopting reusable packaging to reduce waste and costs.

Returnable transport packaging (RTP) is widely used in automotive and logistics sectors.

Customization & Industry-Specific Solutions

Companies are investing in tailored packaging solutions to cater to specific product needs.

Examples include specialized pharmaceutical packaging, food-safe materials, and impact-resistant industrial packaging.

Conclusion

Packaging protection is more than just a means of enclosing a product—it is a crucial aspect of logistics, customer satisfaction, and sustainability. As industries continue to innovate, the focus is shifting toward smarter, more sustainable packaging solutions that balance durability, cost-efficiency, and environmental responsibility.

With advancements in material science, automation, and eco-friendly alternatives, the future of packaging protection looks promising. Whether for retail, industrial, or e-commerce applications, investing in reliable protective packaging is essential for businesses looking to improve product safety, reduce costs, and enhance overall efficiency

0 notes

Text

Bio-based Foam Market Growth Boosted by Innovations in Sustainable Manufacturing Processes

The global bio-based foam market is witnessing significant growth due to rising environmental concerns and an increasing preference for sustainable alternatives. Bio-based foams, derived from renewable natural resources such as plants, offer an eco-friendly solution to traditional petroleum-based foams. These foams find applications in various industries, including automotive, construction, packaging, and furniture, making them essential for sustainable product development.

Market Drivers and Trends

Several key factors are driving the growth of the bio-based foam market. First, there is a growing demand for sustainable and eco-friendly materials, driven by increased environmental awareness among consumers and regulatory bodies. Governments worldwide are implementing stringent policies to reduce carbon footprints, which has led industries to adopt greener alternatives. The shift from conventional foam materials, which are derived from petrochemicals, to bio-based options is becoming a necessity in order to comply with these regulations.

The growing demand for bio-based foams is also attributed to the increasing awareness of their benefits, such as reduced environmental impact, biodegradability, and improved performance. Bio-based foams are not only sustainable but also offer superior qualities like high thermal insulation, excellent cushioning properties, and resistance to fire and moisture, making them ideal for use in automotive interiors, furniture, and packaging materials.

Types of Bio-based Foams

The bio-based foam market comprises several types, each serving different applications. The most common types include:

Polyurethane Foam: This is the most widely used type of bio-based foam. It is derived from renewable sources like soybeans, castor oil, and other plant-based oils. Bio-based polyurethane foams are used extensively in the automotive and furniture industries, owing to their lightweight nature and high insulating properties.

Polystyrene Foam: Polystyrene-based foams, made from bio-based resources like starch, are used in packaging applications. They are biodegradable and recyclable, making them a sustainable alternative to conventional plastic foams.

Polyethylene Foam: Bio-based polyethylene foams are produced using natural resources like corn and other bio-based polymers. These foams are used in a wide range of applications, such as packaging, automotive parts, and insulation.

Other Bio-based Foams: Various other types of bio-based foams are under development, such as those made from algae, mushrooms, and waste materials like rice husks. These innovations are aimed at reducing waste and making foam production more sustainable.

Applications of Bio-based Foams

The bio-based foam market is expanding across multiple industries due to its versatility. The automotive industry is one of the largest consumers, using bio-based foams for components such as seat cushions, door panels, and headliners. These foams offer lightweight properties, which contribute to fuel efficiency by reducing vehicle weight.

In the construction sector, bio-based foams are increasingly being used for insulation purposes. Their excellent thermal and acoustic insulation properties make them ideal for improving energy efficiency in buildings. Additionally, bio-based foams are used in packaging materials, providing a biodegradable and sustainable alternative to conventional plastic packaging.

The furniture industry has also adopted bio-based foams for mattresses, cushions, and upholstery. Consumers are increasingly looking for sustainable options in their home furnishings, and bio-based foams offer a great solution. Moreover, the packaging industry is turning to bio-based foams to create eco-friendly, protective packaging that reduces the environmental impact of shipping and handling.

Challenges in the Bio-based Foam Market

While the bio-based foam market offers numerous benefits, there are several challenges that hinder its widespread adoption. The cost of bio-based foams is still higher than that of traditional foams, making them less attractive to price-sensitive industries. This price disparity is mainly due to the higher raw material costs and limited availability of bio-based materials.

Another challenge is the scalability of bio-based foam production. Though the demand for sustainable alternatives is growing, the manufacturing processes for bio-based foams are still being refined to meet global production demands. Additionally, the infrastructure for large-scale production of bio-based materials is not as developed as that for conventional foams.

Future Outlook of the Bio-based Foam Market

Despite these challenges, the future of the bio-based foam market looks promising. Continuous innovations in material science and advancements in manufacturing processes are expected to drive down costs and increase the availability of bio-based foams. Additionally, consumers' growing preference for sustainable products is likely to continue supporting the demand for eco-friendly foams.

As industries seek greener alternatives to reduce their environmental impact, bio-based foams are expected to play a vital role in the global push for sustainability. Governments are also likely to continue implementing policies that support the adoption of bio-based materials, further fueling market growth.

Conclusion

The bio-based foam market is poised for continued growth, driven by increasing demand for sustainable materials across various industries. With ongoing innovations in material technology and production methods, bio-based foams are expected to become more cost-effective and accessible. As consumers and industries alike strive for environmentally responsible solutions, bio-based foams will undoubtedly become an integral part of a sustainable future.

0 notes